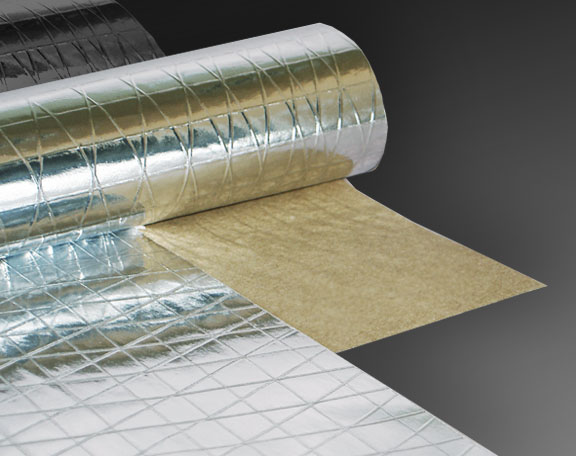

CT-FSKR-0750A thermo - FLAME RETARDANT INSULATION FOIL SCRIM KRAFT FACING & VAPOR BARRIER, HEAT ACTIVATED ADHESIVE

FEATURES:

- High heat reflection, low emissivity

- Good vapor barrier

- added flame retardancy

- Heat activated adhesive, clean and convenient industrial application

- Perforated version available on request. Perforated version can be used for production of heat reflective acoustical boards and breathable reflective insulation

APPLICATION:

- CT-FSKR-0750A thermo can be used as insulation facing - vapor retarder and radiant barrier for different types of insulation

- Heat activated "thermo" adhesive for clean, fast and convenient application without liquid glue

| Facing Composition | Description | Values (English) | Values (Metric) |

|---|---|---|---|

| Foil | Aluminum | 0.28 mil | 7 micron |

| Adhesive | Flame retardant | ------ | ------ |

| Reinforcing | Tri-directional Fiberglass | 2/inch (MD); 3/inch(XD) | 8/100mm(MD); 12/100mm(XD) |

| Kraft | Natural | 30 lbs / 3000 ft2 | 50 g/ m2 |

| Adhesive | PE | 1.0 mil | 25 micron (18-20 g/sq.m) |

| Physical properties | Metric | English | METHOD |

|---|---|---|---|

| Basis weight (area weight) | 110g/sq.m | 22.5 lbs / 1000 ft2 | Scale |

| Permeance (WVTR) | 1.15 ng/N.s | 0.02 perm | ASTM E96, procedure A |

| Tensile strength - MD | 125 N/ 25mm | 28.4 lbs/in | ASTM D828 |

| Tensile strength - XD | 60 N/ 25mm | 13.6 lbs/in | ASTM D828 |

| Bursting strength | 30 N/cm2 | 43.5 psi | ASTM D774 |

| Low temp. resistance | Remains flexible, No delamination | Remains flexible, No delamination | ASTM D1790, 4 hrs @ -40oF (-40oC) |

| High temp. resistance | Remains flexible, No delamination | Remains flexible, No delamination | ASTM D1790, 4 hrs @ +203o F (+95oC) |

| Emissivity | 0.03 | 0.03 | ASTM E408 |

| Flame retardancy | Meet or exceed UL723 25/50 requirements | Meet or exceed UL723 25/50 requirements | ASTM E408 |

| Available roll width | 1.2m, 1.25m | 47”, 49.21” | |

| Roll length | by order | ||

BENEFITS of dry (heat) lamination technology:

- simplify and speed up lamination process,

- make production cleaner and greener (environment friendly) by elimination of liquid glue

- the dry (heat) lamination can be used for the insulation facings without paper as well as traditional paper backed insulation facings

- allow to produce acoustical heat reflective insulation boards and duct wrap by using perforated materials

- allow to manufacture breathable reflective glasswool insulation with reflective properties, which is extremely important for the hot/cold climate

© 2013 Calem Technology Inc. All rights reserved.