CT-FOIL-406A - ECO GRADE RADIANT BARRIER AND VAPOR RETARDER

FEATURES:

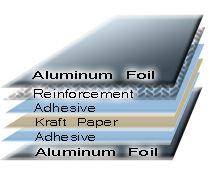

- Double side radiant barrier

- Kraft, tri-directional fiberglass reinforcing

APPLICATION:

May be used in combination with different tapes of fiberglass, mineral wool, and foam insulation.

| Facing Composition | Description | Values (English) | Values (Metric) |

|---|---|---|---|

| Foil | Aluminum | 0.28 mil | 7 micron |

| Reinforcing | Tri-directional Fiberglass | 2/inch (MD) 3/inch (XD) |

8/100 mm 12/100 mm |

| Adhesive | Polyethylene | --- | --- |

| Kraft | Recycled paper | 36.6 lbs/3000 ft2 | 60 g/m2 |

| Adhesive | Polyethylene | ------ | ------ |

| Foil | Aluminum | 0.28 mil | 7 micron |

| Physical Properties | Test Method | Values (English) | Values (Metric) |

|---|---|---|---|

| Basis Weight | Scale | 25.5 lbs / 1000 ft2 | 125 g/ m2 |

| Permeance (WVTR) | ASTM E96, Procedure A | 0.02 perm | 1.15 ng/N.s |

| Tensile Strength - MD | ASTM D828 | 41 lbs/inch | 180 N/25 mm |

| Tensile Strength - XD | ASTM D828 | 18.2 lbs/inch | 80 N/25cm2 |

| Bursting Strength | ASTM D774 | 65 psi | 45 N/cm2 |

| Low Temperature Resistance | ASTM D1790 4 hrs @ -40 oF (-40 oC) |

Remains Flexible No Delamination |

Remains Flexible No Delamination |

| High Temperature Resistance | ASTM D1790 4 hrs @ +240 oF (+116 oC) |

Remains Flexible No Delamination |

Remains Flexible No Delamination |

| Dimensional Stability | ASTM D1204 @ 150 oF (65 oC) | Less than 0.5% | Les than 0.5% |

| Emissivity | ASTM E408 | 0.03 | 0.03 |

| Available Roll Width | --- | 49.2" | 1.25m |

© 2013 Calem Technology Inc. All rights reserved.